| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

| |||||||||||

|

Happy Three Roll Milling

Thursday, July 8, 2021

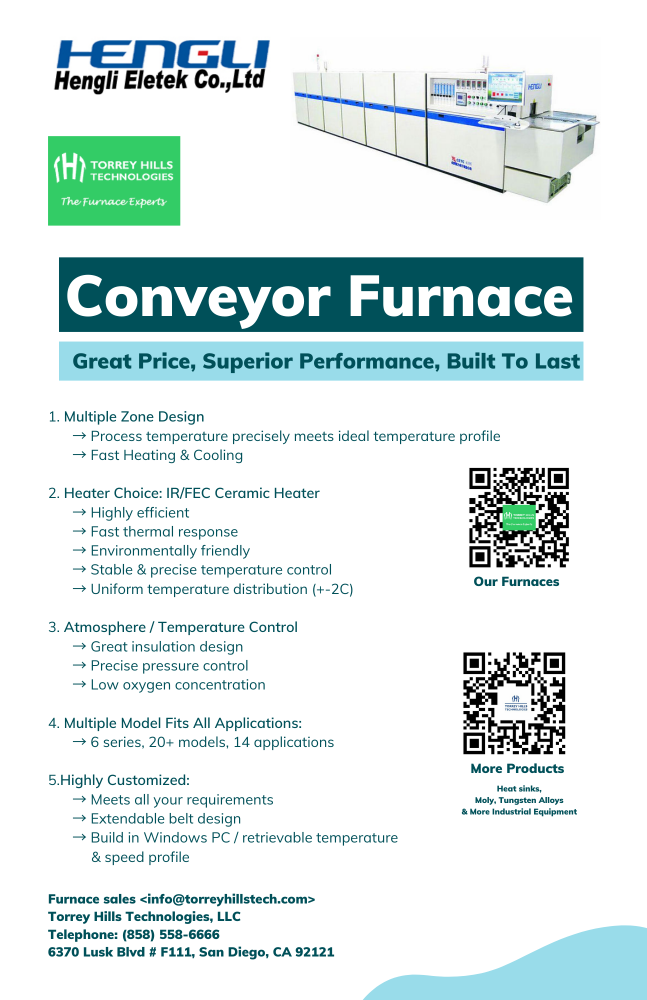

Thermal Processing & Conveyor Belt Furnace

Labels:

belt furnace,

conveyor furnace,

furnace,

heat sinks,

heatsinks,

hengli,

solar dye cells,

thermal,

thermal processing

Location:

San Diego, CA, USA

Tuesday, August 6, 2019

3D Printing Resin Broken Down

Liquid Resin

Liquid resin is a curable photopolymer - it is used as the main material for SLA printers. The resin is hardened by applying focused light or UV light. The liquid resin helps the model have fine details and smooth finishing surfaces. Different combinations of various additives that comprise a resin in different material properties. Some main benefits of using resins are smooth, fine features, high detail, high stiffness, and a good finishing surface. However, resins also have some limitations such as being relatively brittle, not suitable for outdoors use, and susceptible to creep.

4 main groups of resins based on their properties

Standard resins: Best used for rapid prototyping, concept modeling, or art models’ applications due to there low-cost.

Engineering resins: All engineering resins require a post-curing under UV light to achieve their maximum mechanical properties. They provide many mechanism options for the parts such as durable, tough, heat resistant, rubber-like, or ceramic filled.

Dental and medical resins: Biocompatible resins are used to make customized medical equipment. The parts using dental and medical resins later can be steam-sterilized for direct use in operating rooms. These resins also have high resistance to fracture and wear make it ideal to create custom hard splints or retainers.

Castable resins: This kind of resin is ideal for parts with sharp details and smooth finish. When burned, it leaves out no ashes or residue. They are best for jewelry and other small and intricate components.

While most FDM filaments are interchangeable, 3D printing resins are for more specialized products.

Reasons for Resin over Filament

- Durability: Although objects were made by layer to layer of cured resins, they are still not exactly known for their toughness. Most resins are brittle and easy to fail by cracking or shattering. In this case, engineering resin is a solution due to it's customized to simulate the toughness of injection-molded plastics

- Flexibility: There are many resins have high flexibility that can build rubber-like products. They are known for low tensile modulus, high impact resistance, and elongation. However, being so soft can make them hard to print, these soft resins will require supportive structures during the printing process.

- Price: Printing with resins is often more expensive than printing with filaments. A liter of high-quality 3D printing resin will cost 50$ compare to an entire roll of filament of $20. Moreover, SLA often printers require enough resin in the tank that the build platform need to submerge completely.

Making resins with the Three-Roll Mill

Any kind of resin is a result of good mix from combinations of the monomers, oligomers, photoinitiators, and various other additives. Good resin requires a good dispersion of all additives, elements, and a liquid base. These requirements are achievable using the three-roll mill machines. Three-roll mill machine has three horizontal rollers that 2 rollers next to each other will rotate in the opposite direction plus at a different speed. While rotating, any material that is poured in between a tiny gap of feeder roller and the center roller will experience a large amount of shear force which will give a fine dispersion. Therefore, three roll mills are ideal for blending and dispersion of viscous materials like resin. Check out www.Threerollmill.com to learn more.

Post-process of 3D printing resins

Resin 3D printing is an optimal option to produce high details and fine feature products. However, resin 3D printing often requires supportive structures to be attached to the models, and the models need to be arranged at specific angles. These supportive structures later will leave marks and create rough surfaces. Luckily, with proper tools and cautiousness, 3D printing resins are an easy material to post-process.

Basic post processes for 3D printing resins

- Cleaning: It is important to clean all uncured resin from the print. Alcohol or water is used to clean since resin is a liquid material.

Supportive structures removal: Break off the supportive structures will leave bumpy surfaces on the model. Therefore, it is recommended adding extra thickness to the model and then sanded afterward to achieve dimensional accuracy.

- Sanding: This process is to remove any debris leftover after the printing. It can be done with dry or wet sanding tools. Wet sanding often provides a smoother surface to the print.

- Painting: Painting can be done as special requirements. Variety of colors now are available on the market.

- Polishing: This process can help bring back the transparency after sanding. With the use of various compounds, polishing can make the surface even more smooth and clear.

All these post-processes can be done manually or with special devices that are now available for all range from small to big 3D printers.

Advantages and limitations of 3D printing resins

Every technology has its advantages and limitations. Depend on the capability of the printer, the properties of resins using, resin 3D printing also has some advantages and limitations.

Advantages:

- High details: Since the model is built by loading layers of liquid, resin 3D printing will provide more complex geometries and filaments

Smooth surface: Although printing layer by layer with create some layer lines, these lines are extremely small. On some colors of resin, these lines nearly invisible.

- Various material: Nowadays, a wide range of resin materials can manage to provide all common applications and needs. Moreover, specific designs and product can be manufactured with combinations of different resins.

High speed: Resin printing is much faster than comparing to other prototyping methods. High detail features can be produced with hours and still keep the same quality.

Limitations:

- Many supportive structures: Supportive structures will help the models avoid from touching the plate. These structures after being curved, won’t be able to recycle into fresh resin. They become solid and useless.

- Necessary post-process: Post processes are required to do with resin prints before they are ready. Without post-process, model possibly can be ruined and won’t deliver the best quality.

Conclusion

As 3D printers become more affordable, 3D printing will be the fastest-growing manufacturing technology. 3D printing technology is a chance for businesses to increase their competitiveness and innovation. The uses of 3D printing for manufacture, prototype, and especially for medical is beyond astonishing. It is still new and continuously improving and adjusting. With a wide range from manufacturing processes to materials, the industry still has a lot more to achieve in the future. “If a picture is worth a thousand words, a prototype is worth a thousand pictures.”

Friday, August 2, 2019

A Quick Introduction to 3D Printing

3D Printing

Three-dimensional (3D) printing in recent years has become the main focus of public and media attention as technology has at last approached the quality necessary for direct production of end-use devices. 3D printing is a method of manufacturing that materials such as metal or plastic are deposited onto one another in layers to produce a three-

dimensional product and are offered with different options in terms of feature detail,

materials, and costs. 3D printing is a game-changer that allows for the manufacturing of complex geometric shapes that can be mass-customized as compared to traditional manufacturing technologies such as forging, machining, casting, and injection molding. 3D printing has already been proved workable in many medical applications including the manufacture of custom prosthetic devices and dental implants. The most popular methods of standard 3D printing include vat photopolymerization, powder bed fusion, material extrusion, sheet lamination, directed energy deposition,

material jetting, and binder jetting. The industry has realized the manufacturing advantages of these methods and is investing in production systems to create complex structures for rocket engines, airplane parts, customized parts for cars. Although 3D printing technologies have advanced that several materials can be used to manufacture including polymers, ceramics, and metals, the products are still generally limited to a number of compatible materials.

Printing Processes

It can be a big challenge for people that are new to the world of 3D printing to figure out the differences in 3D printing. Like what the difference is between types of 3D printing like SLA and SLS, for example? With so many different acronyms, it can be pretty confusing. Although there are many different printers available, there are only 9 basic types of 3D printing methods that currently exist. With the 3 main methods being: Fused Deposition Modeling (FDM), Stereolithography (SLA) and Selective Laser Sintering (SLS) which all have effective uses for consumers, professionals, and businesses.

Wednesday, July 31, 2019

Three Roll Mills and Thick Film Paste

Introduction

Thick Film Materials is ink paste produced through mixing, kneading, and dispersing of metal powders, glass powders, and inorganic oxides with organic solvent in a three-roll mill. The thick film pastes are screen-printed on ceramic boards or green sheets as circuit patterns and then burned. They are mainly used for various electronic components such as multilayer chip capacitors, chip resistors, etc. These components are used in volume in personal computers, mobile phones, etc. Depending on the application, the paste can act as conductive materials, resistor materials and insulate materials. In conductor compositions, the conductive phase is generally a precious metal or mixture of precious metals. In resistor compositions, the conductive phase is generally a metallic oxide. In dielectric compositions, the functional phase is generally a glass or ceramic.

2. Ingredients of Thick Film Paste

A thick film ink comprises main functional powder, glass frit, transitional metal oxide, dispersing agent, and organic medium, which is typically solvent and organic binder. It serves as a vehicle to disperse the main functional powder.

There are three critical parameters of the paste that related to screen printing: (1) the ratio of the solid contents, (2) the particle size distribution, and (3) viscosity.

The solids content (active element and adhesion element) as a ratio of the total weight of the paste will dramatically affect the ability of the paste to be screened, as well as the density of the fired film. If the solids content is high, the fired film will be dense, but it will also be difficult to screen. A typical value for thick-film conductors is 85-92%.

The solids content (active element and adhesion element) as a ratio of the total weight of the paste will dramatically affect the ability of the paste to be screened, as well as the density of the fired film. If the solids content is high, the fired film will be dense, but it will also be difficult to screen. A typical value for thick-film conductors is 85-92%.

The particle size distribution of a thick film paste is a compromise between screenability and the properties of the fired film. For screenability, it is desirable to have very small particles, but very small particle size in thick film resistors produce parameters that are skewed and not suitable for most circuit applications. Larger particles will obviously be more difficult to screen and may actually block one or more screen opening. Particle size distribution may be measure in a manufacturing environment by the use of a fineness-of-grind (FOG) gauge.

Viscosity is related to the molecular attraction within the body of the liquid and is the ratio of the shear rate of the fluid (in sec-1) to the shear stress (in force per unit area). The viscosity measurement is usually employed by spindle method.

2.1 Functional Ingredients

2.1.1 Conductive Compositions

Any of the noble metals, their alloys or mixture may be used as the conductive phase. Noble metals such as Ag, Pt, and Pb can be used and their alloys can be Pt/Au, Pd/Ag, Pd/Au and Ag/Pt/Pd. The particle size of conductive phase should be in the range 0.5-1.0 μm and a surface area of 1-12 m2/g. The more preferable amount is 50-75 wt % of the compositions, excluding the organic medium.

2.1.2 Resistor Compositions

The thick film resistor composites generally comprise a mixture of electrically conductive materials finely dispersed in an insulative glassy phase matrix. The compositions should provide a wide range of sheet resistance (0.5 Ω/□ and higher than 1×109 Ω/□ and any intermediate resistance value)

The viscosity will be in the range of about 15-50 pascal-seconds (Brookfield RVT, 10 rpm, #5 spindle)

2.1.3 Dielectric Composition

The main functional phase of the dielectric paste is ceramic compositions from Al2O3, SiO2, CaO and MgO or the mixtures.

2.2 Glass Frit

2.2 Glass Frit

The glass frit powder is essential to the composition to promote adhesion to the substrate and densification of the composition upon processing. The glass frit should be 3 to 4 wt% of the whole ink amount. The glass frits most preferably used are the borosilicate frits, such as lead borosilicate frit, bismuth, cadmium, barium, calcium or other alkaline earth borosilicate frits. The preparation of such glass frits is well-known and consists in melting together the constituents, and pouring such molten composition into water to form the frit. The main materials are the transition metal oxide generally comprising zinc oxide, titanium oxide, chromium (III) oxide, cadmium oxide and nickel (II) oxide. To obtain the above desired oxide, the bath ingredients could be any compounds that yield the desired oxides under the usual condition of frit production. For example, boric oxide will be obtained form boric acid, silicon dioxide will be produced from flint, barium oxide will be produced from barium carbonate, etc. The desirable amount is from 0.5 to 2.0 wt%.

2.3 Organic Medium

Organic medium is the solution of organic binder solved into the solvent. The organic solvent amount composing the vehicle should be 0.04 to 0.18 by weight to the whole powder amount.

The solvent system is required to primarily dissolve the polymeric resin system (i.e. organic binder) as well as adequately wet the substrate during the screen-printing operation.

The solvent usually boils within the range of 130-350 °C. Suitable solvents include kerosene, mineral spirits, dibutylphthalate, butyl carbitol, butyl carbitol acetate, hexylene glycol and high-boiling alcohols and alcohol esters. Various combinations of these and other solvents are formulated to obtain the desired viscosity, volatility, and compatibility with dielectric tape.

The primary function of organic binder is to bind together the main functional materials, such as conductive particles or resistor particles. In general, these consist of polyesters, acrylics, vinyl, or polyurethane polymers, and they may be combined to obtain optimum properties.

The most common resin is ethyl cellulose. However, resins such as ethylhydroxyethyl cellulose, wood rosin, mixtures of ethyl cellulose and phenolic resins, polymerthacrylates of lower alcohols, and monobutyl ether or ethylene glycol monoacetate can also be used. The weight-average molecular weight of the organic binder is preferably 100,000 to 1,300. The content of the organic binder is preferably 2 to 15 wt% in the whole ink.

In addition, the thixotropic agents and wetting agents are added into the solvent. Thixiotropic agents are commonly hydrogenated castor oil, and its derivatives are and ethyl cellulose. Of course, it is not always necessary to incorporate a thixotropic agent since the solvent/resin properties couple with the shear thinning inherent in any suspension may alone be suitable in this regard. The wetting agents include phosphate esters and soy lecithin.

2.4 Other Additives

Additives may also be employed to fine-tune viscosity for good screen-printing characteristics enabling accurate and reproducible production, or to modify the binder system acting as, for example, a plasticizer to enhance flex properties. The additives account for 0.05 to 5.0 wt% in the whole ink.

3. Process Thick Film Paste

The ingredients (the particulate inorganic solids and the organic medium) of the paste are first weighed together in a container. The components are then vigorously mixed to form a uniform blend, and are then passed through three-roll mill to achieve a good dispersion of particles. A three roll mill is composed of three horizontally positioned rolls rotating at opposite directions and different speeds. When material is passed through the first nip, between the feed roll and the center oil, it is subjected to high shear force resulting in mixing, refining, dispersing and/or homogenizing of the material. When the material passed through the second nip, between the center roll and the discharge roll, it is again subjected to high shear force resulting in further mixing, refining, dispersing and/or homogenizing of the material. Milled material is removed from the apron roll by a knife that runs against the roll. The cycle can be repeated to improve dispersion until equilibrium is reached. A Hegman gauge is used to determine the state of dispersion of the particles in the paste. The satisfactory dispersion will give a fourth scratch point of 10-18 μm. The viscosity of the paste is typically within the following ranges when measured at room temperature on Brookfield viscometers at low, moderate and high shear rates (showed in Table 1).

Examples are showed in Table 2-4 [1].

Table 2. Copper ink

|

Copper (mean particle size 1.0 μm)

|

|

|

Glass frit (Nippon Electric Glass Co. GA-9 which

has the composition PbO.B2O3.SiO2)

|

3

|

|

ZnO (Kanto Chemical Co.)

|

1

|

|

i-BMA, -MeSt resin (Sekisui Chemical Inc.

IBS-6) Weight average molecular weight 4750

|

10

|

|

solvent (Kanto Chemical Co., butylcarbitol

acetate)

|

6.6

|

|

Dispersing agent (alkyl-substituted

polyoxyethylene phosphate or alkylallyl-

substituted polyoxyethylene phosphate

|

0.4

|

Table 3. Gold ink

|

Gold (mean particle size 1.0 μm)

|

79 (parts by weight)

|

|

Glass frit (Nippon Electric Glass Co. GA-9 which

has the composition PbO.B2O3, SiO2)

|

3

|

|

ZnO (Kanto Chemical Co.)

|

1

|

|

i-BMA, -MeSt resin (Sekisui Chemical Inc.

IBS-6) Weight average molecular weight 1360

|

9

|

|

solvent (Kanto Chemical Co., butylcarbitol

acetate)

|

7.6

|

|

Dispersing agent (alkyl-substituted

polyoxyethylene phosphate or alkylallyl-

substituted polyoxyethylene phosphate

|

0.4

|

Table 4. Silver ink

|

Silver (mean particle size 2.0 μm)

|

|

|

Glass frit (Nippon Electric Glass Co. GA-9)

|

3

|

|

ZnO (Kanto Chemical Co.)

|

1

|

|

i-BMA, -MeSt resin (Sekisui Chemical Inc.

IBS-6) Weight average molecular weight 32060

|

10

|

|

solvent (Kanto Chemical Co., butylcarbitol

acetate)

|

6.6

|

|

Dispersing agent (alkyl-substituted

polyoxyethylene phosphate or alkylallyl-

substituted polyoxyethylene phosphate

|

0.4

|

4.2 Resistor Paste

|

Example 1

|

Example 2

|

|

|

TiSi2

|

29.2%

|

12%

|

|

Ti5Si3

|

0%

|

18%

|

|

Al2O3

|

2.6%

|

0%

|

|

Glass I

|

68.2%

|

35%

|

|

Glass II

|

0%

|

35%

|

The first glass: 5-10% SiO2, 30-50% BaO, 40-60% B2O3 and 1 to 5% CuO

The Second glass” 50 to 70% B2O3, 25 to 40% SrO, and 2 to 10% SiO2

4.3 Dielectric Paste

Table 6. Example of dielectric paste [3]

|

Compositions

|

|||||||

|

SiO2

|

B2O3

|

Al2O3

|

BaO

|

Na2O

|

|

Li2O

|

|

|

Glass 1

|

60

|

30

|

5

|

3

|

1

|

0.6

|

0.4

|

|

Al2O3

|

SiO2

|

CaO

|

MgO

|

||||

|

Ceramic 1

|

100

|

0

|

0

|

0

|

|||

|

Ceramic 2

|

95

|

5

|

0

|

0

|

|||

|

Note: Sample 1 is ceramic 1 + glass 1 with ration of 50/50, Sample 2 is ceramic 2 + glass

2 with ration of 50/50

|

|||||||

In Conclusion

The three-roll mill has been used in thick film materials manufactures. The mills with different sizes are good for laboratories and small production runs to large batch production. Our products [4] provide a great deal of flexibility in designing a machine that best meets the customers’ specific application. We pursue our products to reach the most precise requirements for dispersing, refining, shearing, particle size reduction, homogenizing, blending, mixing and de-aearting. We continue to seek out unique applications with our high quality product and service.

References:

1 Satoru Fujii, Hirotoshi Watanabe, Conductive ink composition and method of forming a conductive thick film pattern, 1992, US Patent 5366760

2 Charles C. Y. Kuo, Thick film Resistive Paint and Resistors made therefrom, 1985, US Patent 4639391

3 Satorn Yuhaku, Seiichi Nakatani, Tsutomu Nishimura, and Toru Ishida, Dielectric paste and method of manufacturing the paste, 1986 US Patent 4812422

4 http://www.threerollmill.com

Subscribe to:

Comments (Atom)